In semiconductor fabrication, a filled FOUP with 25 pieces of wafer transport through different stations and thousands processes.

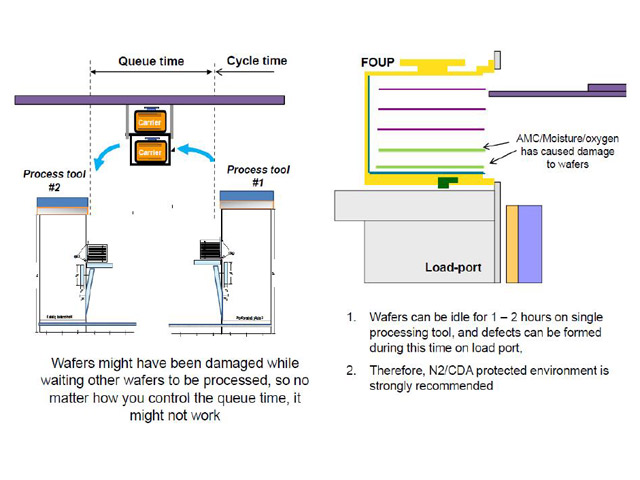

Based on different process, we can’t precisely estimate the waiting time of each wafer on different stations and machines.

At this point, the Airborne Molecular Contamination (AMC), particle, humidity, and oxygen inside the FOUP might damage wafers, even cause the risk of yield loss.

We strongly recommend our customer to implement N2 tool load port retrofit.

By purging N2 or XCDA air to reduce AMC, humidity, and oxygen inside the FOUP, helps our customers to achieve better product quality and effectively control product Q-time.