Internal N2 Tool Load Port

Purging N2 or XCDA air to reduce AMC, humidity, and oxygen inside the FOUP, helps our customers to achieve better product quality and effectively control in product Q-time. Our retrofit docking plates cover 95% of Load port types of Industry used. (TDK、Sinfonia、Rorze、Brooks、Hirata etc.) Apply on both Entegris and Shin-Etsu FOUP types. Purge with fixed flow or mass flow control (MFC). Components like MFC, Pressure gauge of inlet/outlet, O2 meter, Humidity sensor, and temperature sensor will collect and upload values to HOST for FDC. Recommend to implement air curtain to prevent the high humidity gas of the EFEM (Equipment Front End Module) from invading into the FOUP when the door is opened. To ensure the humidity remains in an acceptable range on the surface of each wafer.

Product Specification

- Main controller Dimension: L-35 W-9 H-60 cm

- Brach controller Dimension: L-17 W-9 H-60 cm

- Main controller Weight: 20 KG

- Branch controller Weight: 15 KG

- Standard Spec.: Mass Flow Controller, 7”inch touch panel (HMI)

Hardware Highlights

- Tidy and concise controller for fast installation and maintenance.

- Feasibility for all types of Load port.

- New docking plate applies on both Entegris and Shin-Etsu FOUP types.

- Fixed flow or mass flow control (MFC) N2/XCDA purge.

- Anti-statistic material and well-deformed silicone nozzles to achieve better airtightness, less impact on robot hand’s position and prevent wafer scratch accident happens.

- Safety device includes interlock, reed switch and environmental O2 sensor.

- From QC to installation and follow-up document, we provide the most comprehensive product report for each case to our customers.

- User-friendly UI, easy to interact with the product. The standard menu includes authority management, Chart output, Event, and Log record.

- Real-time display for PTLP status, automatically produce charts of flow, O2, and humidity value for User to understand the status by timeline.

Service Highlights

- Cooperate with hotline service, provide active and immediate assistance.

- Familiar with Load Port operation, we provide high independence of work.

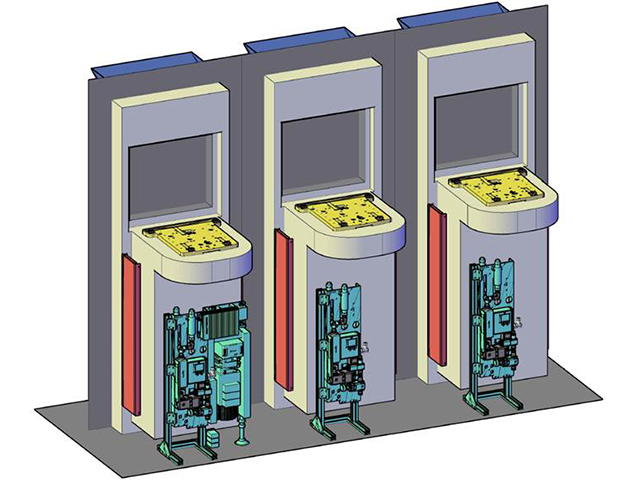

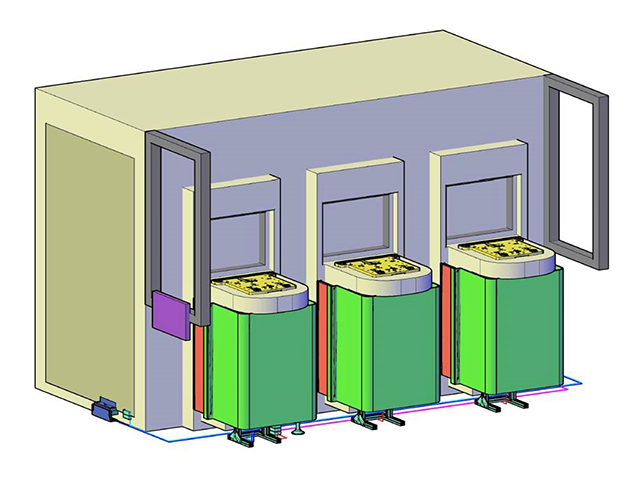

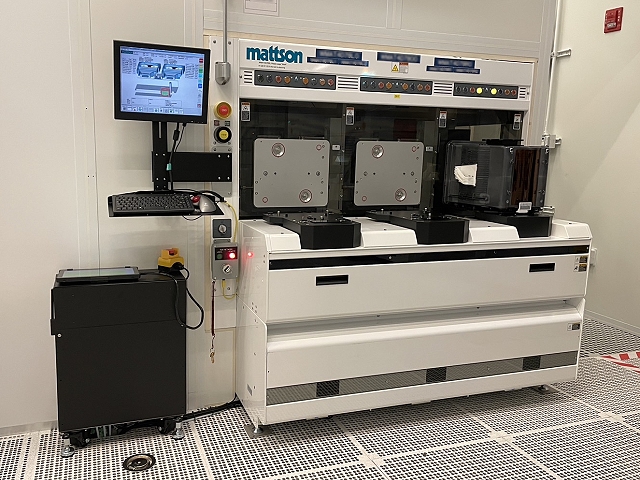

- Synergy laboratory equipped with various types of load port and FOUP, to verify product performance.

- Integration service provided with highly system integration capacity from hardware to software.

Photo description

Product Specification

- Main controller Dimension: L-35 W-9 H-60 cm

- Brach controller Dimension: L-17 W-9 H-60 cm

- Main controller Weight: 20 KG

- Branch controller Weight: 15 KG

- Standard Spec.: Mass Flow Controller, 7”inch touch panel (HMI)